Product for agriculture

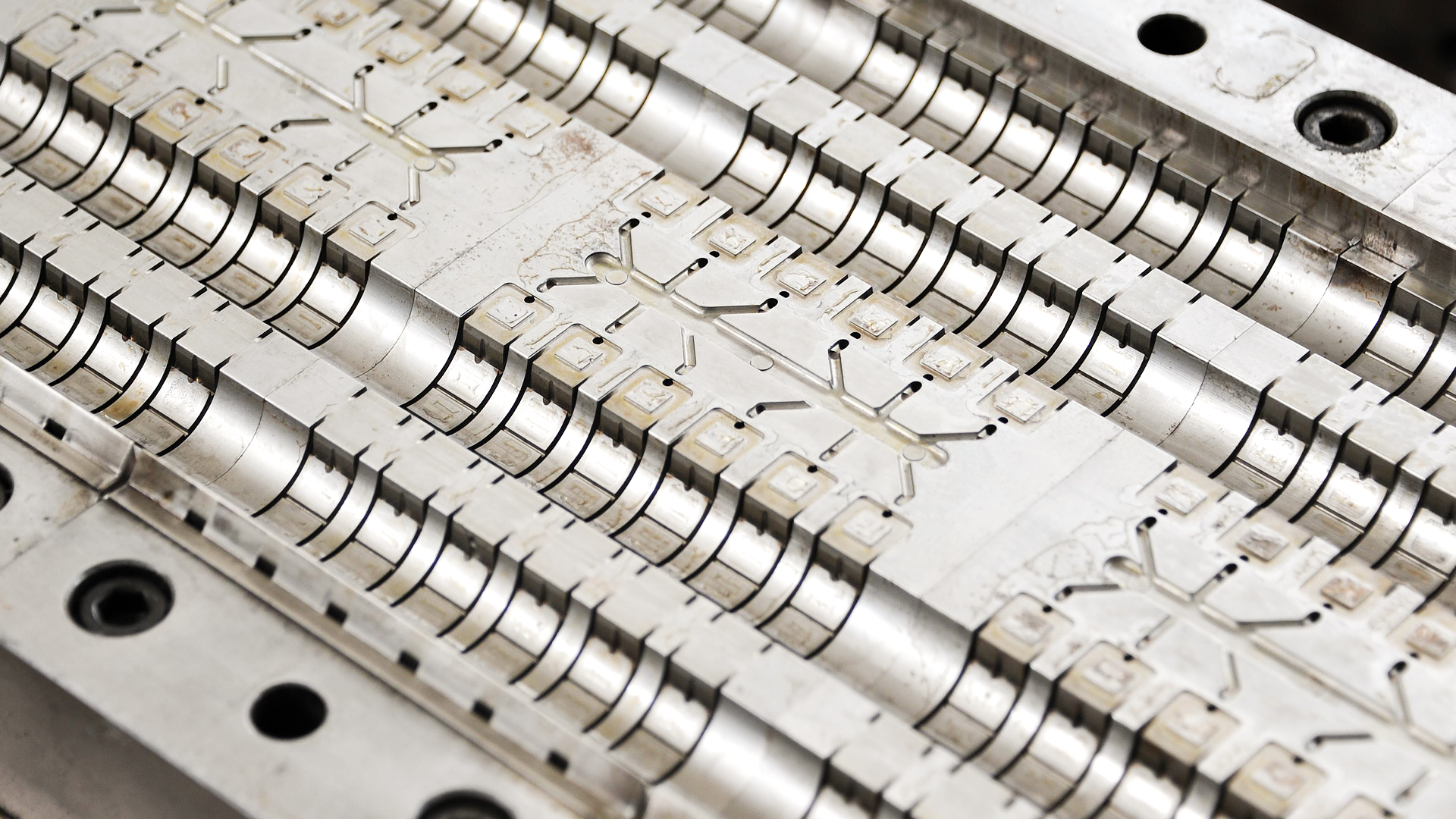

Read allMoulding plastic components is the "core business" of the company, which boasts over 40 years of experience in the field.

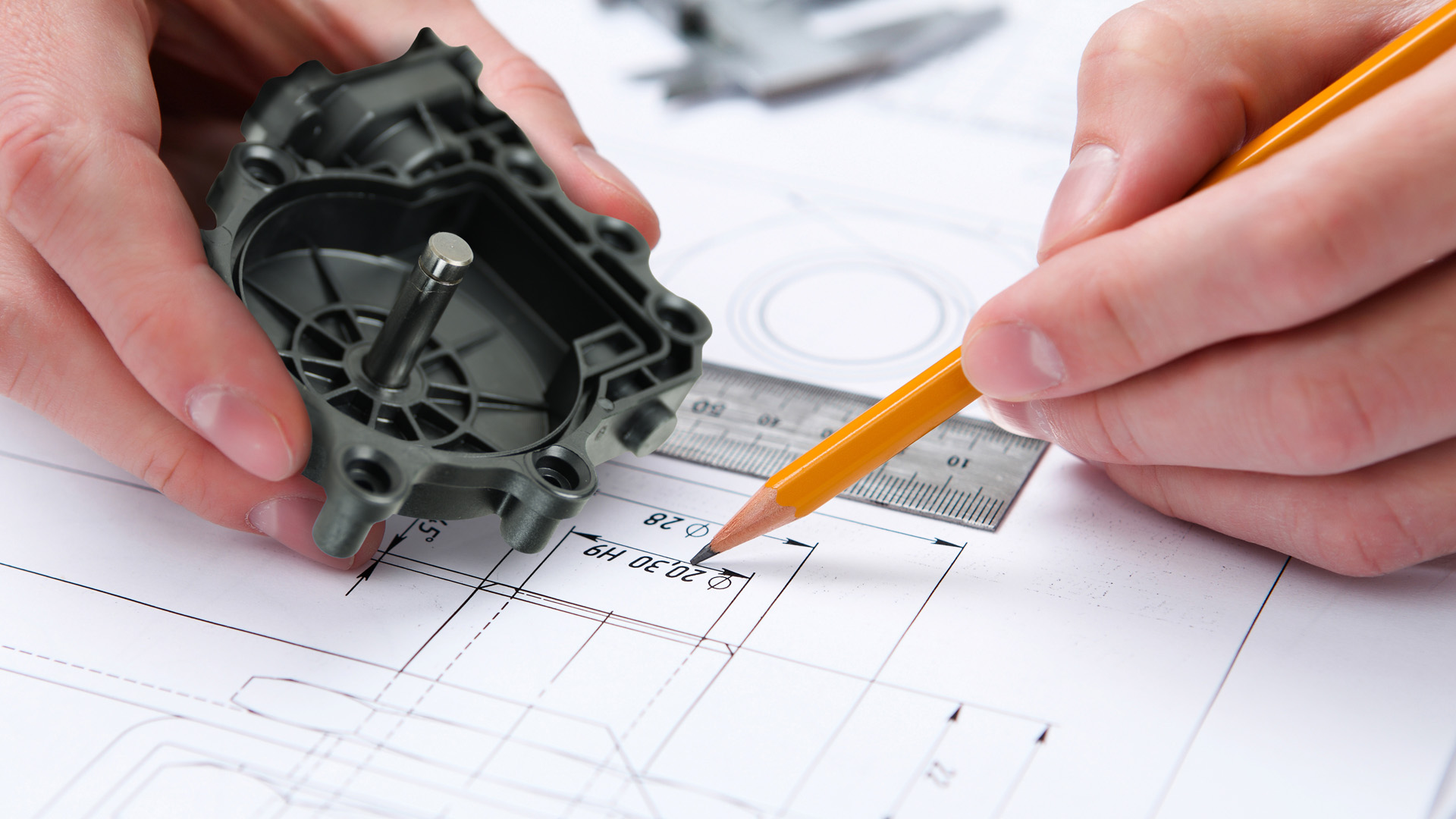

At BS, we design with flexibility and experience. During the design phase, we are the meeting point between the needs of the customer and the equipment manufacturer: we verify the cost of the project according to the aesthetic and functional needs of the customer, the realisation needs of the mould makers and the characteristics of the material that will be used.

We start from the customer’s idea and design the production equipment needed to create it, and then we manufacture the moulds and test them.

We provide a three-dimensional prototyping service to view the finished product and carry out any modifications before irreversible choices have been made.

At BS, we can perform carry out mould maintenance and less demanding modifications. For more complex action and the manufacturing of new moulds, we use specialised partners with whom we have a long-established co-operation.

We are also specialised in testing new and modified moulds on behalf of customers or the manufacturers themselves.