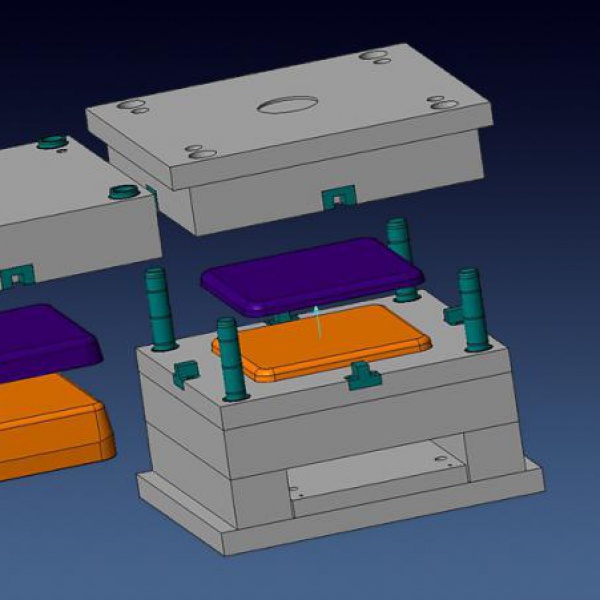

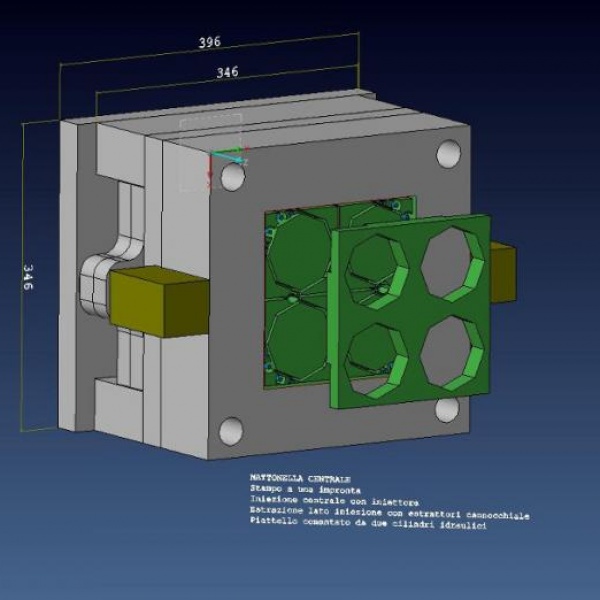

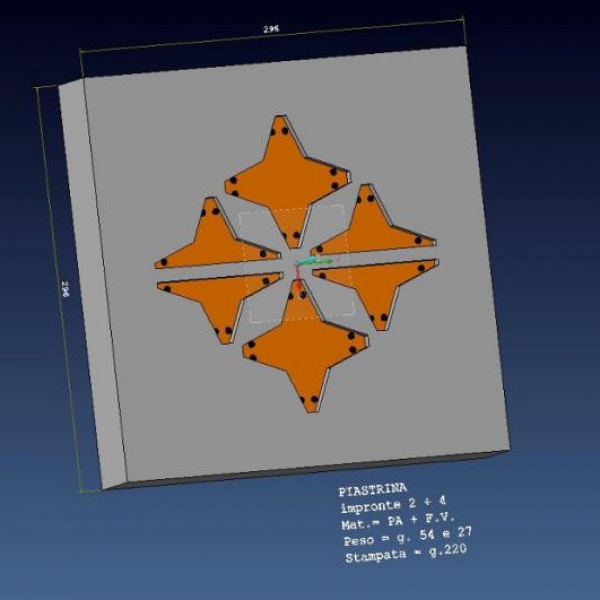

At BS, the mould manufacturing process starts from the CAD 3D design that enables the creation of mathematical models to manufacture equipment and, if need be, the physical prototype for the necessary dimensional and constructive verifications and the simulation of the production phase.

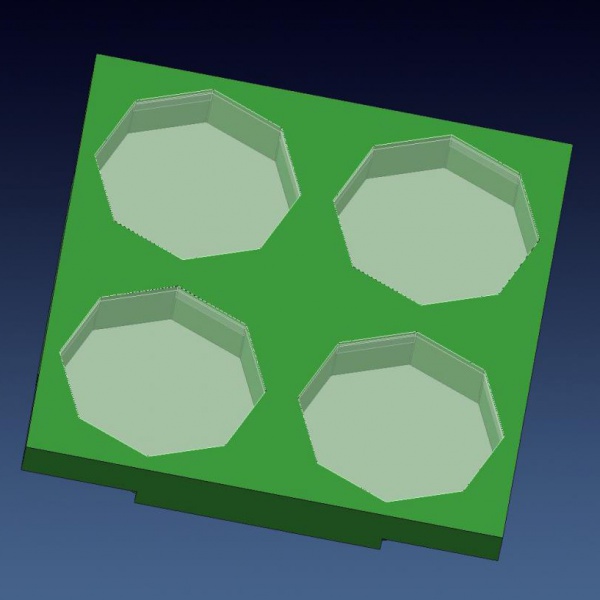

Following the prototyping stage, the actual construction of the single or multiple production mould is carried out, according to the dimensions of the part and the industrialisation needs required by the customer and optimised for the chemical-physical features of the material used in the production.

When ready, the mould is tested at our plant and then transferred to its final destination, or it can remain in our plant should the customer wish to use our production service on behalf of a third party.

The experience of BS on production materials and equipment further guarantee a customised and extremely flexible service also for the needs of small series production.